REHABILITATION AND MODIFICATION OF CENTRAL EMERGENCY GENERATOR

NASA DRYDEN FLIGHT RESEARCH CENTER

Edwards Air Force Base, CA

Stronghold Engineering, Inc. served as the prime contractor for this project that called for installation of two new emergency generators. The system interfaces with the existing main substation to provide power to critical facilities at the Flight Research Center in the event of a power outage.

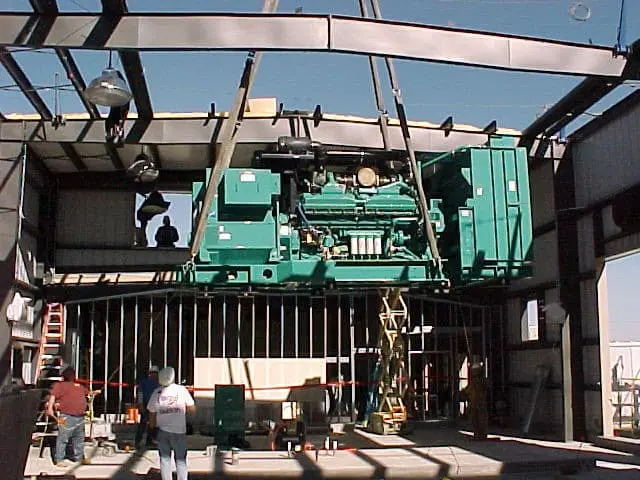

The electrical portion of work was completed with more than 525 feet of underground piping, 680 feet of above ground steel piping, two (2) emergency generators, paralleling switchgear, a distribution panel (DPA), three (3) panel boards, two (2) lighting control panels, two (2) pad-mounted transformers, 44 wiring devices, six (6) disconnect switches, GRC conduit and fittings, PVC conduit and fittings, 600V cable (#12 – #1 at 58,000 ft.), 3,000 feet of 15KV cable (3,000 ft.) and 36 15KV terminations, a ground rod and weld system and fire alarm system. The fuel system consisted of a 10,000 gallon fuel storage tank, fuel oil purifier, overflow tank with pump and 390 feet of piping for the fuel lines.

Specifically the site required a great deal of various construction activities which consisted of Site work: survey; remove fencing; rough grading (26,750 sq. ft.); form and pour 5,130 square feet of concrete for the building pad, building footings, equipment pads, fuel tank pad and an 18″ x 18″, 68’ concrete pipe trench was installed. The pre-engineered metal building was delivered to the site, erected and anchored to the slab with more than 90 bolts. The building was insulated and furnished with doors, windows, and a metal rolling door. The interior of the building was built out with metal stud framing (4,000 sq. ft.), drywall (4,500 sq. ft.), flooring and finished with a heat resistant, highly durable paint.

Stronghold’s strategies for mitigating construction impact included the recommendation of a metal building to house the generators in lieu of a masonry building. This value engineering suggestion provided a substantial cost savings of $800,000 to the government. Additional strategies included: dissemination of progress meeting minutes to facility users; outage and cutover notices; environmental controls for noise, dust and fumes; signage to update occupants; look-ahead schedules; three-phase quality assurance inspections; onsite, fully-staffed office; and weekly progress meetings.