From day one, Stronghold chose to be a company that provided high-quality, full-service construction. One of the company’s core values is commitment to its clients, industry, and team. No matter how difficult or unique a project is, Stronghold sees it as an opportunity to build construction excellence.

The team reflected on 32 years of outstanding projects to highlight a few that demonstrate Stronghold’s commitment to excelling in its field.

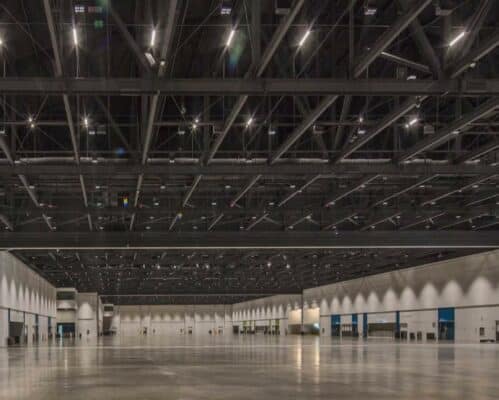

San Jose Convention Center

After 6 months of planning for the San Jose Convention Center renovations, Stronghold completed all major construction on this $20 million job on a quick eight-week turnaround with minimal downtime to conventions.

Spanning across 143,000 sq. ft, the Stronghold team completed three convention halls ahead of schedule and under budget, including installing two new state of the art lighting systems for maintenance and productions, a state of the art speaker system, a new fire alarm system, new structural beams, a new cable tray system, and more.

To meet the tight timeline, crews worked 12 hours a day, 6-7 days a week and multiple trades had to work in the same spaces at a very fast pace. At one point, the team had 65 pieces of equipment running at the same time—boom lifts, scissor lifts, forklifts, roll-off dumpsters, and more. After 54,000 intense man hours of work, the project finished with zero safety incidents.

Thanks to the state of the art upgrades and quality work done by Stronghold in 2017, the San Jose Convention Center attracts major companies and their events which will increase city revenue significantly. Additionally, the convention center’s energy usage will be reduced by 50%, saving them $1.5 million a year. Stronghold won the American Public Works Association Project of the Year in the Sustainable/Green category for this project.

BEQ San Clemente Island

Stronghold teamed with Ravatt-Albrecht & Associates of Santa Maria, CA, to design and build the Bachelor Enlisted Quarters (BEQ) on San Clemente Island for the United States Department of the Navy in 2013.

This $26 million project involved a photovoltaic energy generation system and wind energy electrical power generation equipment, allowing the BEQ to be almost completely off the grid. The building’s plumbing system was set up with a solar domestic hot water system accompanied by a dual plumbing grey water system. The grey water is provided by the wastewater treatment plant that was installed as part of this project.

Creating this LEED Platinum building was a logistically challenging project. All materials for this project had to be barged to the island, including the materials needed to establish the concrete batch plant that Stronghold built on the island to provide for their concrete and mortar needs. Personnel for this project were flown to the island from various airports in Southern California, resulting in ongoing, complex flight and material coordinations.

This project provided a much needed upgraded BEQ for the navy personnel working on the island in addition to a more capable and efficient wastewater treatment plant system for the whole Wilson Cove community. The building performs extremely well and provides the men and women enlisted with the naval services with a clean and comfortable building to call home.

Stronghold was able to adapt and overcome in many of the challenges that are presented while building a project on a remote island.

The new BEQ on San Clemente Island was honored by the USGBC Central Coast of California Chapter at their annual Green Awards, and the project was awarded an Honorable Mention for LEED Platinum Certified.

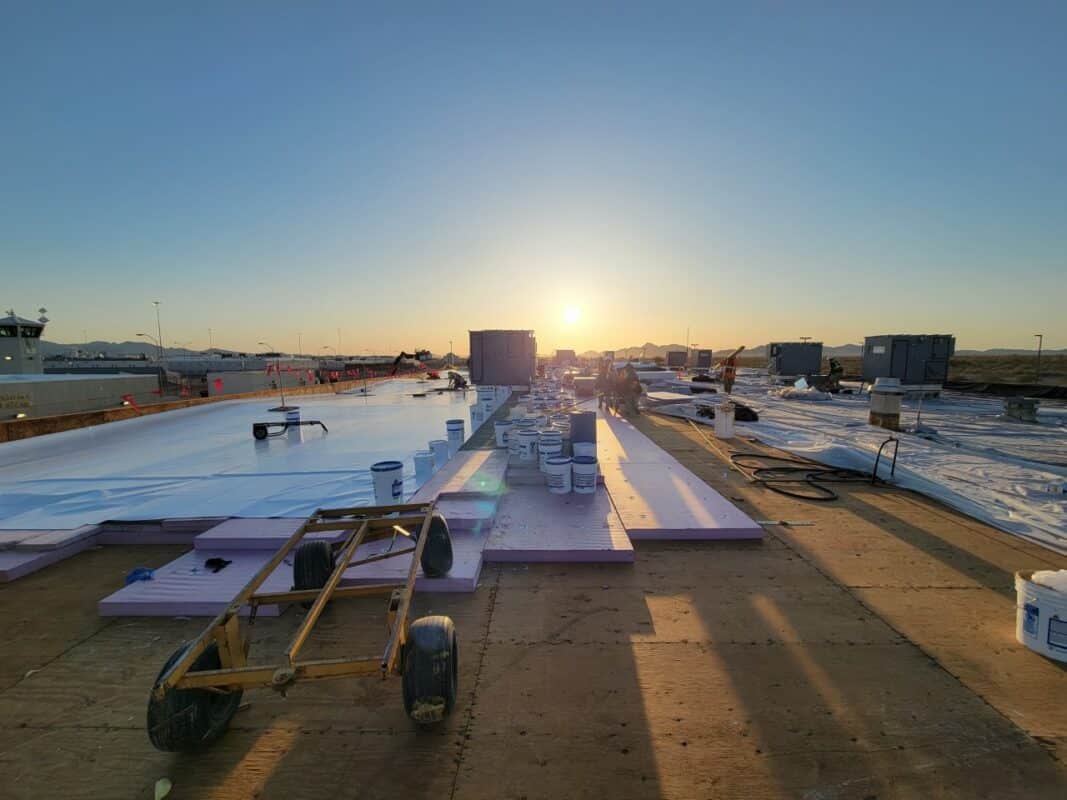

Ironwood State Prison HVAC System

Ironwood State Prison is the biggest project that Stronghold has performed to date. At this $120 million project, Stronghold has demonstrated its capacity to perform well on projects that are both large and extremely complex.

Due to the size of the location and security requirements surrounding the prison, the project has been intricate from the beginning. This project spans across 90 separate buildings. Each building has to be closed out as if it were one separate project, so a tedious process must occur over 90 different times throughout this project, requiring a significant amount of paperwork and tracking.

Some of the challenges faced thus far by the team include taking inventory of all tools, staging materials before they’re hauled inside, and clearing all employees by security two weeks in advance. The extreme heat has added an extra element of difficulty—temperatures reach over 120℉ in the summer and consistently average 116℉ from May to October.

Stronghold’s work will provide an updated cooling system to buildings that were previously fed by swamp coolers that kept the internal temperature around 100℉ degrees. The new air handler will be fed by a chilled water plant and water loop, all constructed by Stronghold.

Upon completion of the Ironwood State Prison project, Stronghold will submit their work for award consideration.

Commitment at Stronghold

These three projects are just the tip of the iceberg when it comes to Stronghold’s commitment to building construction excellence. Stronghold doesn’t shy away from a challenge, and they view each new job as an opportunity for growth.

For more information on other outstanding work done by the team, visit Stronghold’s Projects page.